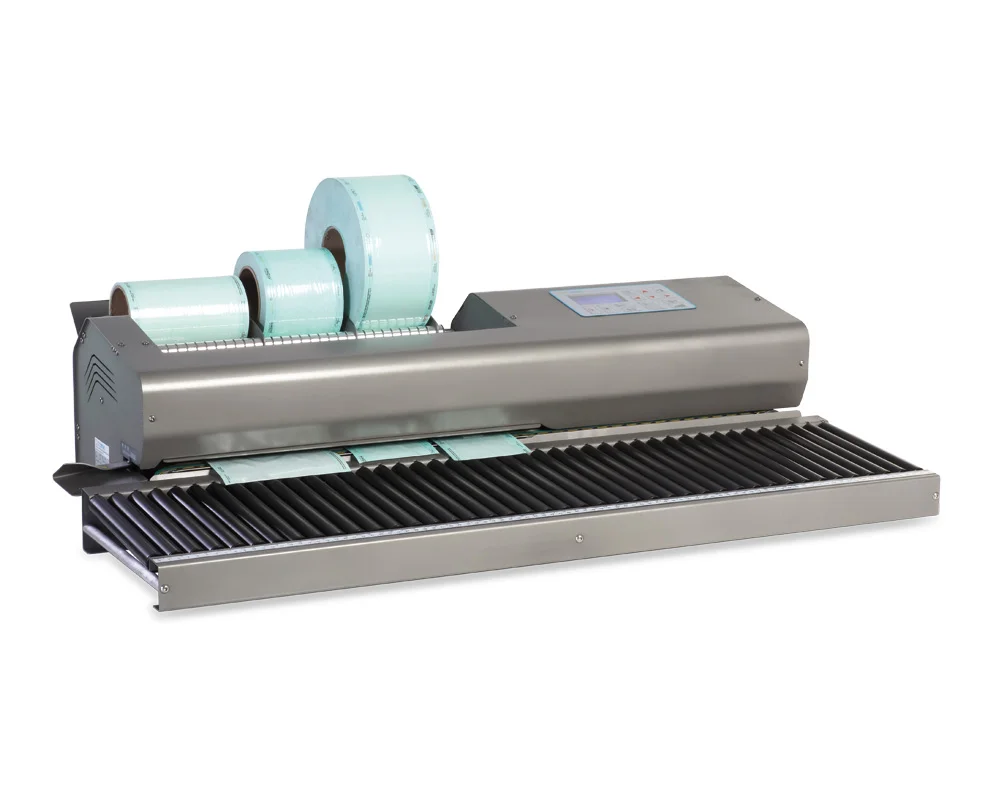

- For entire sterilization required places

- Easy and ergonomic use

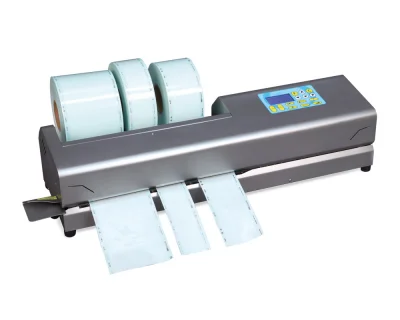

- Automatic Pouch Maker and microprocessor controlled

- Temperature fluctuation ±1°C with PID controls

- Easy settings via switch membrane panel

- Multiple reel loading feature

- Produces 4.000 pouches per hour

- Maximum seal width 400mm.

- Language options and signals when pre-set bundle quantity is produced

- Corresponds to DIN 58953-7

Full Automatic Heating Sealer

When packing materials for medical supplies and products need to be sealed tightly, a Medical Sealing Machine can be used. Heat Sealer's purpose is to provide airtight and leak-proof seals that protect the packaged goods' sterility and integrity. Pouch Sealers use heat or pressure on a variety of packing materials, including pouches, bags, or containers, to form a tight seal.

Sterilization Packing Devices are frequently used to package sterile equipment, drugs, bandages, and other medical supplies in healthcare institutions, laboratories, and pharmaceutical manufacturing.

The sealing process helps to protect the contents from contamination, maintain their sterility, and extend their shelf life. Also, packaging before putting products in a steam sterilizer is necessary to protect the items from contamination, maintain their sterility, ensure proper identification and traceability, and facilitate efficient management of sterilized inventory in healthcare settings. The sealing machine can have printing or cutting features along with the sealing

Full Automatic Heating Sealer: Ensuring Reliable and Sterile Sealing for Medical Use

In sterile medical environments, proper packaging is critical to maintaining the sterility of medical instruments and supplies. A full automatic heating sealer is an essential piece of equipment in ensuring airtight, secure seals for sterilization pouches. Whether for use in hospitals, clinics, or sterile processing departments, these medical sealing machines provide consistent, high-quality sealing for medical packaging, ensuring that instruments remain uncontaminated until they are needed.

Key Features of the Full Automatic Heating Sealer

1. Precise Temperature Control

The efficiency of a medical heat sealer relies heavily on its ability to maintain precise temperature control. This feature ensures that the heat applied during the sealing process is consistent, guaranteeing that each pouch is securely sealed without damaging the contents. Proper sealing prevents contamination and ensures the sterility of the instruments.

2. Automatic Functionality for Speed and Efficiency

One of the main benefits of a heat sealer for sterilization pouches is its ability to perform repetitive sealing tasks without manual intervention. This automatic functionality significantly reduces the risk of human error and speeds up the packaging process, making it ideal for busy sterile processing departments. The machine’s ability to seal quickly and accurately allows healthcare facilities to maintain a steady workflow.

3. Compatibility with Medical Packaging Materials

Medical sealing machines are designed to work with a variety of packaging materials used in sterile processing, such as Tyvek, medical-grade paper, and plastic film. The versatility of these machines ensures that they can be used across different sterilization processes, from steam to gas sterilization, without compromising the integrity of the seal.

4. Built-in Quality Control Mechanisms

A reliable medical sealer is equipped with advanced quality control systems, such as sensors and alarms, to detect any potential sealing issues. This includes monitoring the sealing temperature and pressure, ensuring that the seal is applied uniformly across the packaging material. Should any discrepancies occur, the machine can halt the process, preventing improperly sealed pouches from being used in medical procedures.

Applications of Medical Sealing Machines in Healthcare

1. Sterile Processing Departments

In healthcare facilities, sterile processing heat sealers are essential for preparing medical instruments for sterilization. By securely sealing instruments in sterilization pouches, these machines ensure that the tools remain sterile until they are used in surgeries or other medical procedures. With automatic sealing technology, staff can quickly process large volumes of instruments while ensuring quality and safety.

2. Surgical Centers

Surgical tools must be properly sealed and sterilized before each procedure. The use of a medical sealing machine guarantees that the instruments remain uncontaminated, minimizing the risk of infection during surgery. The automatic functionality also reduces the time required for packaging, helping surgical centers maintain a smooth workflow.

3. Dental Clinics and Outpatient Facilities

For smaller healthcare settings such as dental clinics and outpatient facilities, an automatic heat sealing machine offers a fast, efficient solution for preparing sterilization pouches. These machines ensure that tools like dental instruments and other medical devices are sealed securely and ready for immediate use.

Benefits of Using a Medical Heat Sealer

1. Enhanced Sterility Assurance

With precise control over the sealing process, a medical heat sealer guarantees the highest level of sterility assurance. The secure seals prevent any contaminants from entering the packaging, ensuring that sterilized instruments remain sterile until use. This is crucial for maintaining patient safety and preventing post-operative infections.

2. Reduced Human Error

Manual sealing can lead to errors such as uneven seals or improper sealing temperatures. By utilizing an automatic heat sealing machine, healthcare facilities can minimize these risks and ensure consistent sealing quality for every pouch. Automation also speeds up the packaging process, allowing staff to focus on other critical tasks.

3. Cost-Efficient and Time-Saving

Automated sealing machines reduce labor costs and save time, especially in busy environments like hospitals and clinics. With the ability to seal multiple pouches efficiently, these machines increase productivity without compromising on safety or quality. Moreover, the durability of the machines ensures a long lifespan, making them a valuable investment for any healthcare facility.